- Open Hours:

- / +86 155 121 630 16

Reverse Dutch Twill Mesh

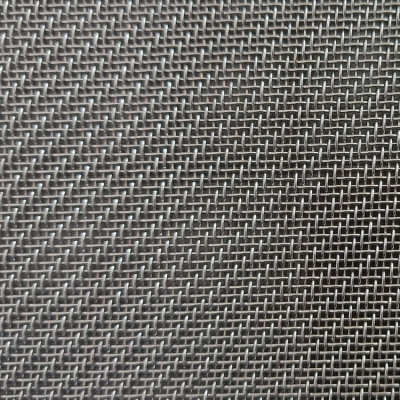

Reverse Dutch Twilled Weave An important version of the reverse dutch weave is the reverse dutch twilled weave. With this weave, the warp wires are also relatively thin – as in the case of the normal reverse dutch weave. The difference is the twilled weave pattern of the shute wires. This means that the warp wires are not as heavily deformed and physically stressed as in the case of plain weaves. The strength of this weave design is its suitability for applications that are subject to high levels of mechanical stress.

Raw Material: Stainless steel wire 304, 304L, 316, 316L, other metal material can be customized.

Weave type: Reverse Twill Dutch Weave (RTD)

Hight Tensile Reverse Dutch Twill Filter belts Standard specifications

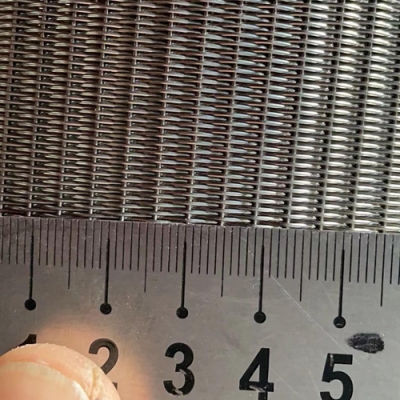

48 × 10 mesh RDPW 400 nominal micron.

72 × 15 mesh RDTW 250 nominal micron.

132 × 16 mesh RDTW 200 nominal micron.

152 × 24 mesh RDTW 115 nominal micron.

260 × 33 mesh RDTW 75 nominal micron.

General Mesh:400×120, 325×39, 260×40, 228×36,160 x25,160 x24,152 x24.132 x18,132 x16,72×15, etc.

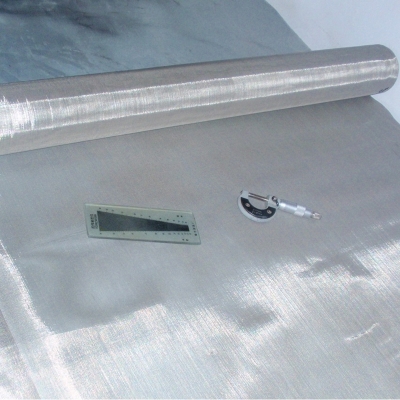

Roll width: 67mm, 95mm, 97mm, 127mm, 133mm, 150mm, 157mm,300mm, 400mm, Max width 50cm

Roll length: 10m, 60” or 120' (Can be customized)Roll length: 10m, 60” or 120' (Can be customized)

Packing :

Waterproof brown paper for moisture resistance.

Plastic paper for dust resistance.

Wooden box or pallet for convenient to load and transport.

Features:

Smooth surface.

High hardness.

Zero aperture.

Chemical resistance.

Acid and alkali resistance.

Rust and corrosion resistance.

High tensile strength than the plain weave woven wire mesh.

Outstanding filtration performance.

Applications

Reverse dutch woven wire mesh is widely used for filtering in various industries.Aerospace.Petroleum.Chemical industry.Chemical fiber.Machinery.Plastic products.Conveying.Other industries.Package

Send Email

Send Email 15512163016

15512163016