- Open Hours:

- / +86 155 121 630 16

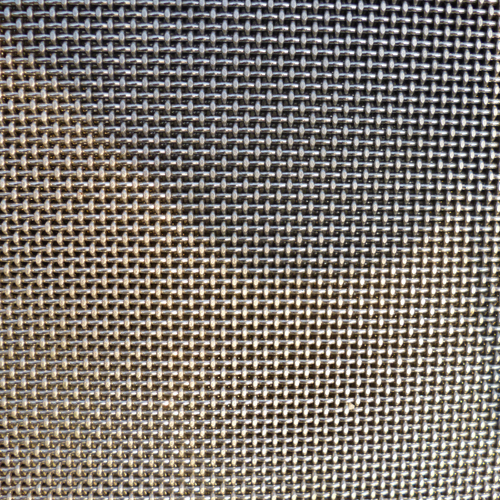

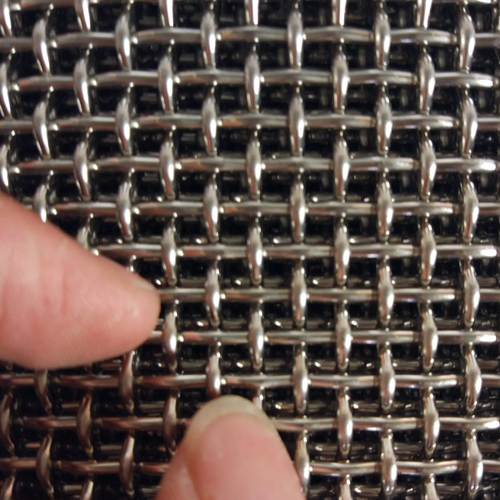

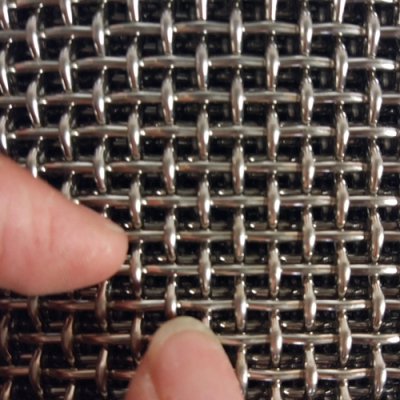

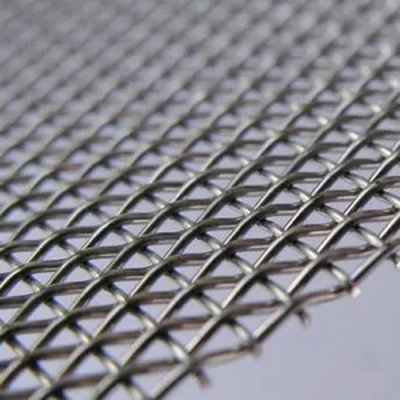

Stainless Steel Woven Mesh Panel

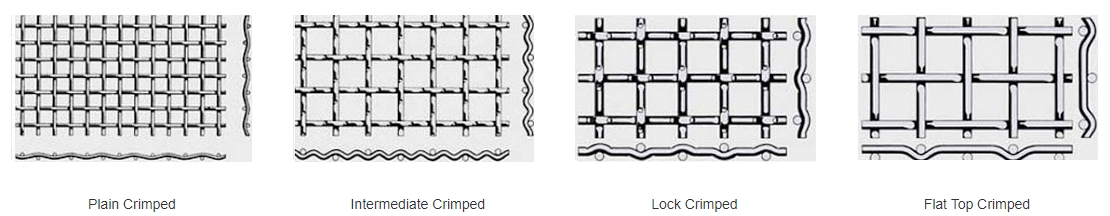

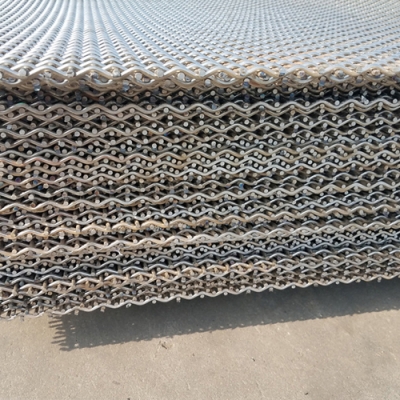

Stainless Steel Woven wire Cloth is woven to size in the same way cloth is woven on a loom. The Woven wire Woven Wire mesh panel Crimp Styles types :

Plain Weave/Double Crimp Woven Wire,Lock Crimp,Double Crimp,Inter crimp,Flat Top.

|

Lock crimp: Lock crimp is comprised of pre-crimped wire featuring the formation of knuckles or bumps over intersecting sets of wires. This locks the mesh in place to create an extremely rigid product.

Double crimp: Double crimp wire mesh cloth exhibits a pattern of warp wires passing over and underfill wires.

Intercrimp: Commonly used for screens and architectural applications, intercrimp woven wire mesh provides superior strength and stability, while offering a rigid mesh solution.

Flat top: As the name implies, the flat top crimp style features a smooth top plane that facilitates the flow of materials.

Common Woven Wire Cloth Materials include:

Stainless Steel; Wire 304

Stainless Steel Wire; 304L

Stainless Steel Wire; 316

Stainless Steel Wire; 316L

Copper and Copper Alloys: Copper, Brass, Bronze, Phosphor Bronze

Stainless steel wire mesh, specifically Type 304 stainless steel, is the most popular material for producing woven wire cloth. Also known as 18-8 because of its 18 percent chromium and eight percent nickel components,

304 is a basic stainless alloy that offers a combination of strength, corrosion resistance and affordability. Type 304 stainless steel is normally the best option when manufacturing grilles,

vents or filters used for the general screening of liquids, powders, abrasives and solids.

woven wire mesh; marco mesh; wire fabrication

Fabricated Woven Wire Basket

Woven Wire Mesh; wire mesh

Woven Wire Mesh Fencing

Woven Wire Mesh; wire mesh; marco wire mesh

Woven Steel Wire Handrail

marco wire mesh; wire; woven wire

Wire Mesh Screen

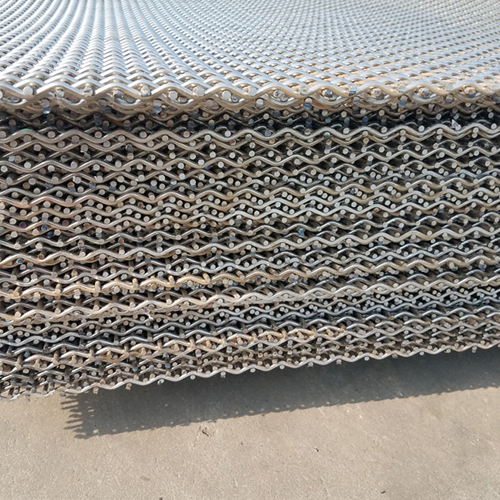

Woven wire mesh also known as woven wire cloth, are woven on looms, a process that is similar to the one used to weave clothing. The mesh can consist of various crimping patterns for the interlocking segments. This interlocking method, which entails the precise arrangement of the wires over and under one another prior to crimping them into place, creates a product that’s strong and reliable. The high-precision manufacturing process makes woven wire cloth more labor-intensive to produce therefore it is typically more expensive than welded wire mesh.

Woven Wire Mesh Crimp and Weave Styles

Wire openings and sizes range broadly. Marco Specialty Steel offers many different weave patterns and pre-crimp styles. Below are examples of crimp and weave styles that are available. See our Crimp and Weave Styles page for more detailed information.

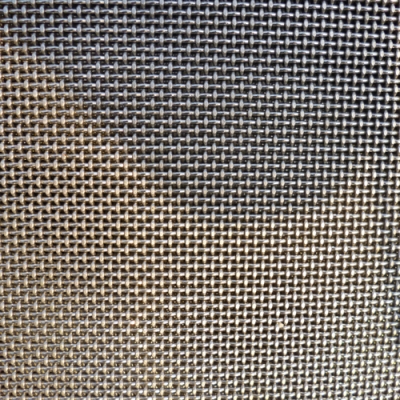

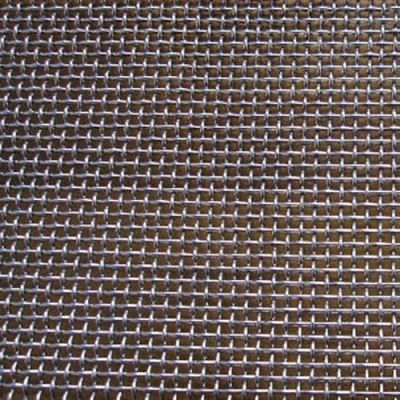

Mesh Size: 4mesh x 4mesh ,6mesh x 6mesh ,8mesh x 8mesh

The Wire Diameter: 0.30mm-2.0mm

This wire cloth is commonly used to make strainers, filter screens, and sieves.

304 stainless steel has good corrosion and abrasion resistance.

316 stainless steel has excellent corrosion and abrasion resistance. Use it in food-processing applications; it is able to withstand corrosive solutions and harsh cleaning.

Stainless steel is the optimum solution for your woven mesh needs. By selecting stainless steel you will utilise its numerous benefits including:

✔ Long term performance

✔ Minimal maintenance

✔ Strength

✔ Life cycle costing

✔ Low environmental impact

Stainless Steel Woven Wire Mesh is manufactured by weaving longitudinal and transverse wires together. Commercial / Industrial grade mesh also known as wire cloth and gauze is extensively used for:

Industry for filtration, screening / sieving and food pressing/ drying

ultrasonic cleaning systems

Industry for Hollander Mesh & Bolting Cloth

Architecture for function and appearance both internally and externally

Bushfire Mesh part of your solution to bushfire protection

Window & Door Mesh part of your solution for stopping insects, intruders & ember

Send Email

Send Email 15512163016

15512163016